The Manufacturing Process

Shoes are one of those products that we wear daily and is a necessity. Although this is a necessity, no one ever seems to ever wonder how the shoes that everyone wears are produced. Well in the manufacturing process there are many steps, parts of a shoe and as well as materials. There are many different materials for shoes. There are certain ones for sport shoes, dress shoes, boots, sandals and more. Some materials are used to make the footwear comfortable, to be able to protect from injuries, or to make it look very exquisite.

Some materials include:

-fabric

-plastic

-rubber

-foams

-metallic

-wood

-leather

Some materials include:

-fabric

-plastic

-rubber

-foams

-metallic

-wood

-leather

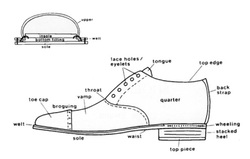

Shoe making can or is considered a traditional handicraft profession. There are many parts to a shoe such as the sole, insole, outsole, midsole, heel, and vamp or upper. More than 200 operations are required for making a pair of shoes. However, with the development of modern machines, a pair of shoes can be made in very less time as each step in its manufacturing is generally performed by a separate footwear making machine. There are also many departments when it comes to manufacturing the product such as click or cutting department that deals with the top part of the shoe and use leather or other materials to cut out various shapes that will eventually for the upper. It is the first process in the making of a pair of shoes. Leather is usually used in this department where the leather is carefully selected and the clicker will proceed to cut the shape of the upper, by hand, from the high quality hides. This is a skilled and specialist job because any flaws in the leather must be worked around, and as leather is very expensive any waste must also be kept to a minimum. After this process there is the closing or machining department which deals with sewing all the components together and as well adding the eyelets where the shoelaces would come from. Next is the lasting and making department which deals with molding the finished uppers into a shape of the foot and as well as adding the plastic shapes that stimulates the foot shape. In that department they add all the soles to it as well. Then there is the finishing department which mainly deals with trimming heels, polishing and buffing soles, making sure that the edge is waxed, waterproof, stained and polished, adding finishing touches and then finally making it finished.